News

Revolutionizing Garment Hardware: Why Sourcing Managers are Switching from Brass to Stainless Steel in 2026

Revolutionizing Garment Hardware: Why Sourcing Managers are Switching from Brass to Stainless Steel in 2026

In the volatile global trade landscape of 2026, garment sourcing managers for leading US and European brands are facing a critical challenge: skyrocketing raw material costs. As copper prices continue to fluctuate at historic highs, the strategic shift from traditional Brass to Stainless Steel fasteners has evolved from a cost-saving tactic to an industry standard for premium quality and compliance.

The Strategic Edge: Benefits of Stainless Steel Fasteners

1. Significant Cost Reduction (Steel-for-Copper Strategy)

According to recent industry analysis, switching to stainless steel can reduce the procurement cost of hardware components by 15% to 25%

2. Superior Safety & Compliance (Lead-Free & Nickel-Free)

For brands exporting to the US (CPSIA) or European (REACH) markets, chemical compliance is non-negotiable.

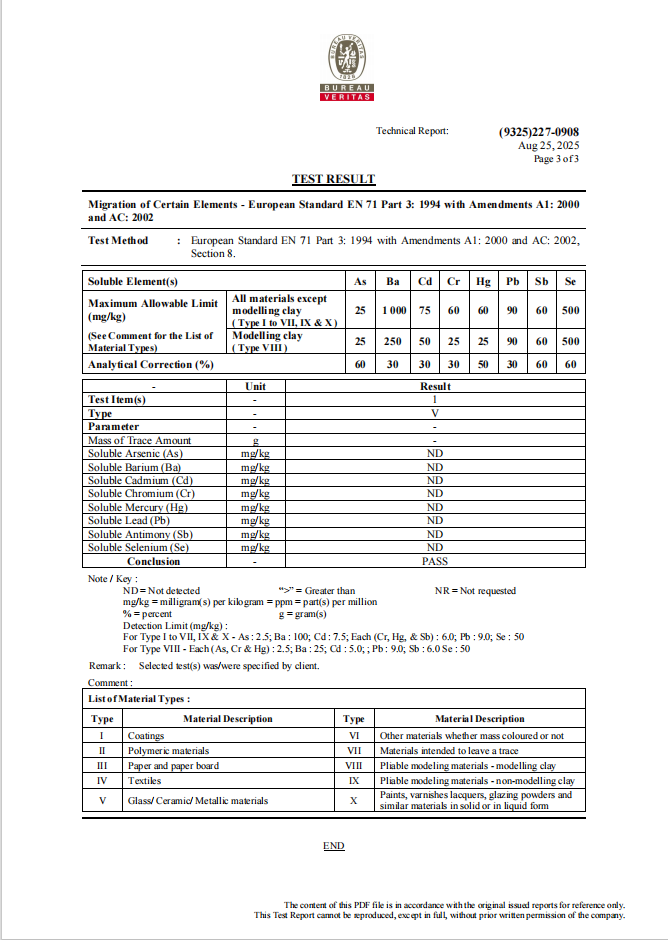

Certified Purity: Our latest technical reports from Bureau Veritas (BV) confirm that our stainless steel components pass the rigorous European Standard EN 71 Part 3

.

Zero Migration: Testing shows Non-Detected (ND) levels for soluble Lead (Pb), Cadmium (Cd), and Mercury (Hg), ensuring your products meet the strictest safety protocols for children’s wear and luxury apparel

.

3. Engineering Excellence: Durability Meets Aesthetics

Stainless steel outperforms brass in high-stress environments like denim and workwear:

Tensile Stability: It maintains consistent snap force even after thousands of cycles

. Corrosion Resistance: Our products undergo extended salt spray testing to guarantee a rust-proof finish that survives heavy industrial laundering

.

Overcoming the "Needle Detection" Hurdle

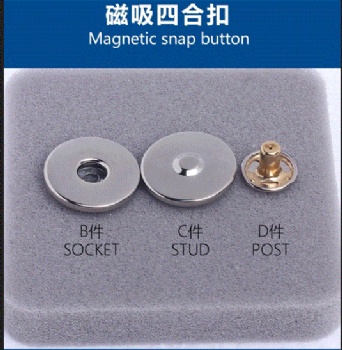

A major concern for North American and European buyers is the Needle Detector (檢針機) test. While low-grade steel can trigger false alarms, Yuanxu Accessories specializes in high-quality Non-Magnetic 304 Stainless Steel and specialized de-magnetization processes

Customization for European & Turkish Designers

Whether you are a designer in Turkey’s booming textile hubs or a sourcing head in Italy, we offer bespoke finishes:

PVD Vacuum Plating: High-adhesion technology that replicates antique brass and vintage gold finishes on stainless steel without the risk of peeling

. Eco-Polishing: For a high-gloss silver look, we offer chemical-free polishing, saving an additional 5% in processing fees while meeting "Green Sourcing" goals

.

Why Partner with Yuanxu Accessories?

We don't just supply buttons; we provide Value Engineering. Our team helps you re-engineer your hardware to optimize weight and cost without sacrificing the "hand-feel" your customers expect

Free Samples for Testing: We provide physical samples for your R&D lab to verify pull strength and chemical safety

. Full Transparency: Every batch is backed by documented test results from world-class labs like Bureau Veritas

.

Optimize Your Supply Chain Today

Upgrade your collection with the strength and safety of stainless steel. Visit our website to explore our full catalog of snap fasteners, rivets, and bespoke metal hardware.

Website:

Inquiries:

Categories

Contact Us

- 0577-65387006

- +86-13587571806

- sales@yuanxufl.com

售前客服

售前客服